A large construction company is building a new 110/20 kV indoor high-voltage substation in the southern region of Ukraine. This substation will become an additional and reliable supplier of electricity for the existing infrastructure of the city. The substation will operate in the control mode from the dispatching console, without the participation of the duty personnel. This will allow you to quickly fix emergency violations and eliminate their consequences without disconnecting customers from the power supply.

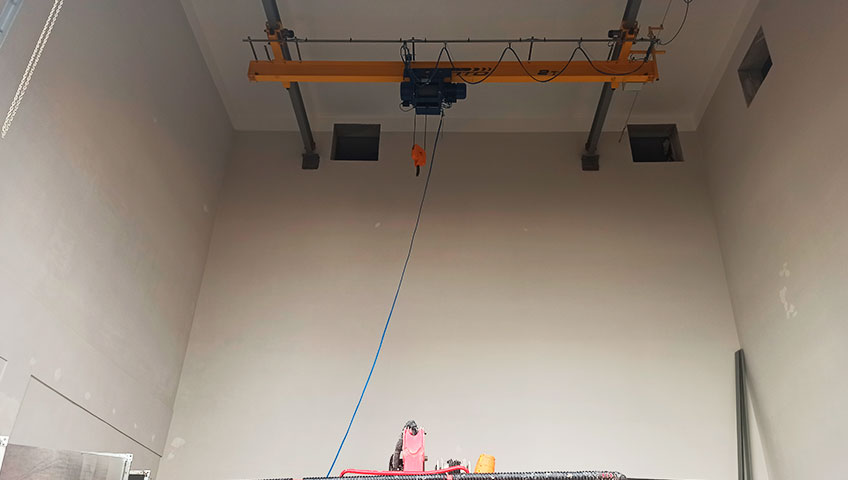

In view of the significant experience in the supply of lifting equipment for similar projects, the Customer decided to entrust the supply of suspended bridge cranes to the Kyiv Crane Machinery Plant LLC. An agreement was signed for the supply of two cranes (marking KMP-5.0-8.0-6.0-10.0-A5 and KMP-2.0-7.0-6.0-10.0-A5), as well as crane runways for them.

Both cranes are completely similar in their operating parameters and equipment, with the exception of the lifting capacity and the speed of lifting and lowering loads (respectively - 5 and 2 tons, 4 and 8 m/min.).

Crane specifications

- lifting height - 10.0 m;

- crane span - 6.0 m;

- trolley travel speed - 20.0 m/min;

- crane movement speed - 20.0 m/min;

- operating mode group according to ISO or GOST - A5 (medium);

- execution - general industrial.

Completion of the supplied crane equipment

- wire rope hoist type MT, geared motors for movement and lifting of production - manufactured by Podem (Bulgaria);

- end beams - manufactured by Kyiv Crane Machinery Plant LLC;

- electrical equipment - manufactured by Schneider Electric (France);

- span bridge - beams of the M series;

- limit switch for hoist movement;

- limit switch for crane movement;

- thermal protection of the hoist motor;

- load limiter;

- main contactor in the circuit;

- pendant control panel;

- power supply to the crane - flexible cable with trolleys on a rope.

At the request of the Customer, our plant completed the delivery of the ordered crane equipment and its installation ahead of schedule, which made it possible to mount the power equipment on time. The supplied cranes will be used for the installation and maintenance of the components of the new high-voltage substation.

Related posts

- Deliveries of 3 overhead bridge cranes to Turkmenistan for the Malay gas condensate field completed

- An overhead crane for a large meat processing plant in the Kharkiv region was manufactured

- An suspension bridge crane was manufactured by order of a large enterprise for the production of plastic products

- A three-span overhead suspension crane was manufactured for the airfield of the State Emergency Service of Ukraine

- Manufactured two overhead cranes by order of the Prydniprovskyi Bio-TPP