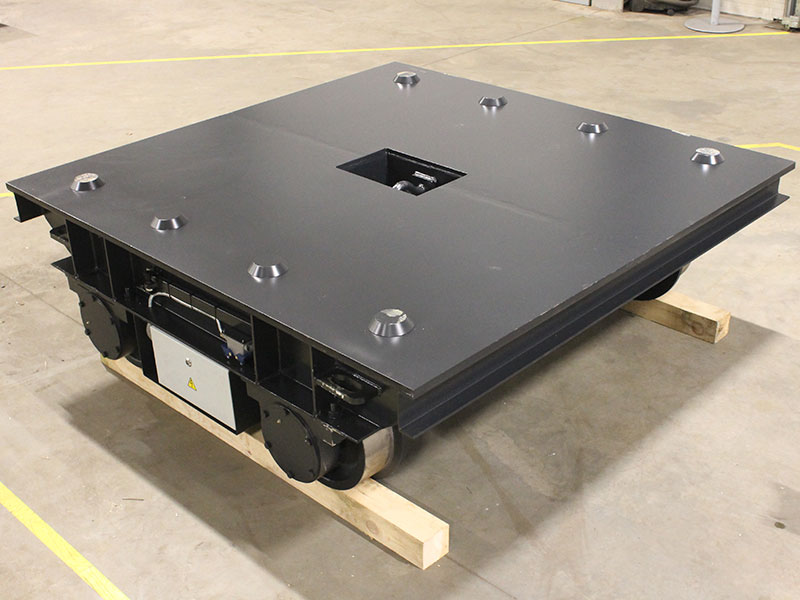

Transfer trolley

Kyiv Crane Machinery Plant LLC produces transfer trolleys for transportation in workshop, warehouse and on the street of bulky cargo:

- machine-building enterprises;

- chemical industry enterprises;

- mining and processing complexes;

- ore mining and processing enterprises;

- metallurgical plants and foundries;

- workshops for the production of metal structures;

- warehouses of finished products.

Types of transfer trolley

Depending on the design features, we produce the following types of transfer trolley:

- rail self-propelled trolley;

- trolleys with battery drive;

- trolleys driven by a winch;

- transfer trolley with manual drive;

- special transfer trolley.

The transport transfer trolley with a drive from the winch is designed to work in rooms with an aggressive, explosive or fire hazardous environment (shot blasting, paint booths) with the location of electrical equipment outside the hazardous environment.

For all types of trolleys, additional accessories can be made to fix and rotate parts.

Main technical characteristics of transfer trolleys

The carrying capacity of the transfer trolley can reach up to 100.0 tons. The distance between the axles of the undercarriage rails (span) is up to 4.0 m, the path length is up to 100.0 m, the speed of the cargo truck is 10.0-40.0 m/min.

Depending on the wishes of the customer, the control of the workshop transport trolley can be carried out through a hanging console or using a radio control system. Operation of the cart is possible at temperatures from -40°C to +70°C in operating modes from light A1-A3 (1Am according to FEM) to very heavy A8 (4m according to FEM).

The complete set of the workshop transport trolley produced by the Kyiv Crane Machinery Plant LLC includes

- metal structures of welded construction trolley steel S235 or S355;

- single-flange or double-flange wheel blocks with axle boxes;

- motor gearboxes manufactured by PodemCrane (Bulgaria) or SEW-Eurodrive (Germany);

- electrical equipment Schneider Electric (France);

- trolley current lead of closed type or cable (with the possibility of installing a cable drum);

- Schneider Electric Altivar type frequency drive;

- by agreement: control from a cable remote control or remote radio control;

- safety devices: trailer travel limit switches, anti-collision device, sound and light warning system during operation, optical sensors for detecting obstacles on the way.

In the assembly of transfer trolleys, we use only high-quality components manufactured by leading world leaders in our industries - this ensures the reliability and durability of our crane equipment.

All products comply with European standards

- Machinery Directive 2006/42/EC (Директива 2006/42/ЕС о безопасности машин и оборудования)

- DIN EN ISO12100: "Safety of machines. Basic terms, general principles of design" (Стандарт EN ISO 12100 Безопасность машин и механизмов)

- EN60204-1: "Safety of machines. Electrical equipment of machines" (EN 60204: Безопасность машин. Электрооборудование машин)

Specialists of the Kyiv Crane Machinery Plant LLC provide a full range of work from the design stage to the commissioning of transfer trolleys and service.

Installation and commissioning works are carried out on the basis of the Permission to perform work of increased danger No. 4114.12.32.

You can buy a transfer trolley with deferred payment from us. A flexible payment system will allow you to operate the trolley and pay the cost according to an agreed individual schedule.

The price of a transfer transport trolley is formed depending on the configuration of the trolley according to your technical specifications. To select the optimal technical solution and prepare a technical and commercial proposal, please fill out a questionnaire on a transfer trolley.

Do you have questions?

Contact us now and

we will help you to find

the right solution.

Request for equipment

Related news

Integration of artificial intelligence into lifting cranes: challenges and prospects

In today’s world, where production efficiency has become a key factor …Two overhead cranes for Production and Design Association “MAANS” were manufactured at Kyiv Crane Machinery Plant

There is a war, but Kyiv Crane Machinery Plant, after relocation …About the work of the Kyiv Crane Machinery Plant in wartime

The life of Ukraine and the whole world is divided into …Manufactured two overhead cranes by order of the Prydniprovskyi Bio-TPP

By order of the Prydniprovskyi Bio-TPP, engaged in the production of …Kyiv Crane Machinery Plant – Industry Leader 2021

The Kyiv Crane Machinery Plant in 2021 produced and shipped more …Kyiv Crane Machinery Plant manufactured two bridge cranes for the Corporation «Biosphere»

Two electric single-girder overhead traveling cranes were manufactured at the Kyiv …Two 20-ton overhead cranes were manufactured for the Ferrexpo Poltava Mining

By order of the Ferrexpo Poltava Mining, the Kyiv Crane Machinery …About the participation of Kyiv Crane Machinery Plant in the work of the XX International Industrial Forum

From 16 to 19 November 2021 in Kyiv in the building …We invite you to the XX International Industrial Forum!

From 16 to 19 November 2021, Kyiv will host the XX …New catalog of wire rope hoists PODEM-2021

PODEM AD is by far the largest European manufacturer of electric …

Other products

- Gantry cranes

- Overhead cranes

- Overhead cranes

- Suspended cranes

- Overhead bridge cranes

- Suspended bridge cranes

- Grab cranes

- Light portable gantry cranes

- Electric wire rope hoists

- Suspended undercrane rails

- Undercrane steel constructions

- Electric cable and busbar supply systems

- Jib cranes

- Explosion proof cranes

- Crane remote control

- Hand hoists

- Crane traverse

- Forklift

- Transfer trolley