We are in a hurry to tell you the great news: another large plant has opened in Ukraine, the main focus of which is the production of roofing and wall sheeting.

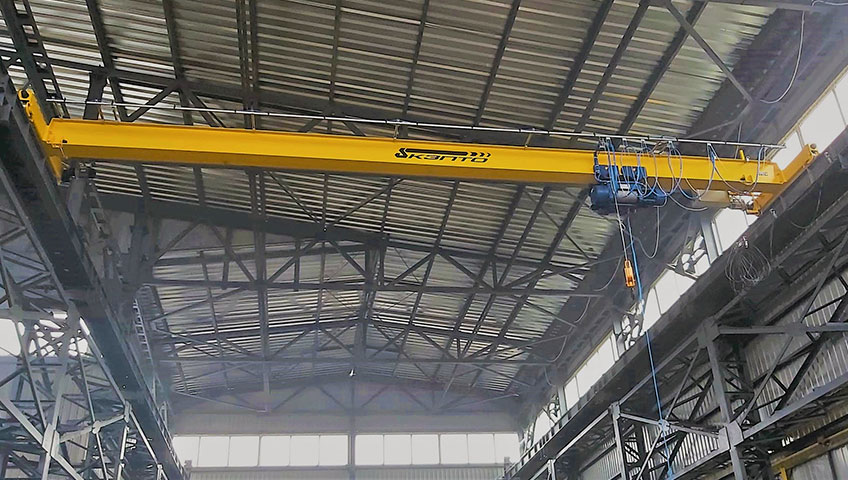

This customer turned to the management of the Kyiv Crane Machinery Plant LLC with a request to manufacture three bridge overhead cranes necessary to accelerate the process of manufacturing corrugated board in a new building under construction.

Having studied in detail the draft technical specifications, as well as the features of the technological process of manufacturing corrugated board and the purpose of each of the necessary cranes, Kyiv Crane Machinery Plant LLC experts made the most optimal decision on the design, manufacture and installation of crane lifting equipment.

Two cranes with a lifting capacity of 3.2 tons and one crane having a lifting capacity of 8.0 tons were designed and manufactured. Otherwise, all three cranes have similar technical characteristics and equipment, namely:

- working lifting height - 7.0 m;

- lifting speed - 0 ... 8.0 m / min;

- movement speed - 0 ... 20.0 m / min;

- permissible operating temperature - -20 ... + 40 ° С;

- permissible relative humidity - not more than 80%;

- group of the operating mode FEM 9.551 / DIN 15020 - 2m, GOST 25835 - A5;

- climatic modification - U2 in accordance with GOST 15150;

- degree of protection of electrical equipment - IP54.

The basic equipment of the overhead cranes was as follows:

- span bridge (box-type beam) - manufactured by Kyiv Crane Machinery Plant LLC (Ukraine);

- MT-type hoists and GO-type end beams - manufactured by РodedemCrane (Bulgaria);

- electrical equipment - Schneider Electric (France);

- cable products - Carpel (Italy);

- frequency inverters of rise and movement;

- hanging 6-button control panel;

- radio control system.

Particular attention was paid to safety devices, namely:

- limit switches for lifting-lowering and movement of the hoist and crane;

- load limiter;

- thermal protection of electric motors;

- main contactor in the circuit;

- phase control relay;

- emergency stop;

- key brand.

Thanks to the detailed WPR plan (work production project) and the high skill of the Kyiv Crane Machinery Plant LLC assembly team, the installation and commissioning work was completed within three days. After passing the static and dynamic tests, an acceptance certificate was signed on the transfer of bridge cranes to the Customer for further work.

Currently, all three bridge cranes are successfully operated: they are used to supply cold rolled steel from galvanized steel to machines, as well as to move finished products to places of assembly and packaging.

Related posts

- Manufactured 3 bridge cranes for a steel plant

- An overhead crane was manufactured for the largest dealer in Ukraine selling agricultural equipment and commercial vehicles

- A 10-ton overhead single-girder crane was manufactured

- An overhead bridge crane was manufactured for a large enterprise for the production of facade systems

- Two bridge cranes were manufactured for a large Ukrainian metal trader