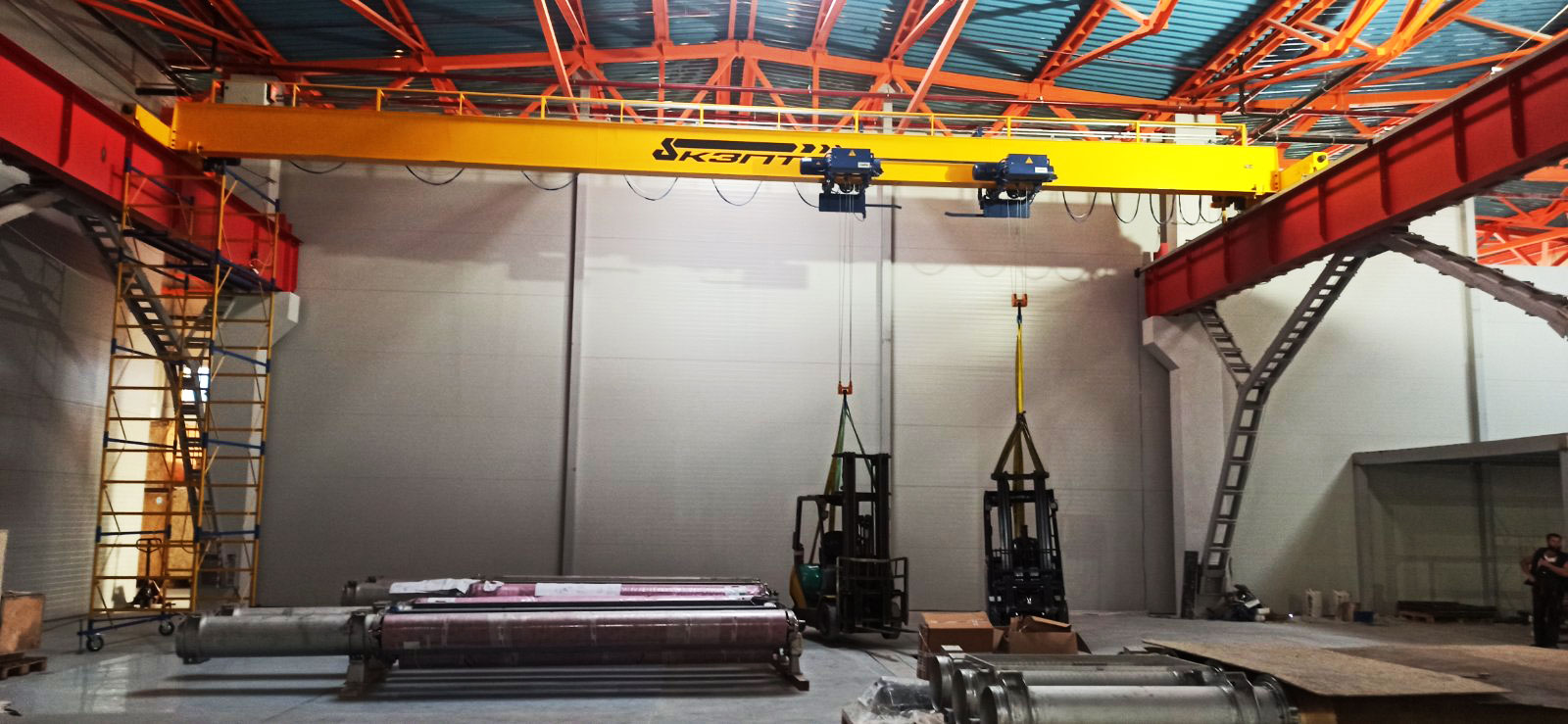

Two electric single-girder overhead traveling cranes were manufactured at the Kyiv Crane Machinery Plant by order of the large international Corporation «Biosphere». Corporation "Biosphere" is well known both to many residents of Ukraine and to foreign consumers of all kinds of goods for the manufacture and storage of food, as well as for sanitary and hygienic needs, sold under the brands: "Freken BOK", "Bonus always +", Smile, PRO service, Novita, Vortex, Eventa, LayKit and many others.

In total, the Corporation required two modern lifting cranes required to support technological processes for the manufacture of products, including the supply of raw materials, maintenance of production equipment, and loading of finished goods into vehicles. When designing the cranes, our designers took into account all the features of technological processes and production areas where it was planned to use the cranes, as well as the wishes of the Customer.

To lighten the weight of the cranes, a single girder design was chosen. It should be noted that both cranes are almost identical in their basic technical characteristics and configuration, except that one of them (marking - KMO-6,3-16,70-7,0-A5) is equipped with one electric hoist with a lifting capacity of 6.3 tons, and the second (marking - KMO-2.5+2.5-16.70-7.0-A5) - with two electric hoists with a carrying capacity of 2.5 tons each, which must work in tandem.

Other main technical characteristics of the cranes:

- lifting height - 7.0 m;

- span - 16.7 m;

- lifting and lowering speed - 6.0/2.0 m/min;

- trolley travel speed - 20.0/5.0 m/min;

- crane movement speed - 40.0/10.0 m/min;

- operating mode group according to ISO or GOST - A5 (medium);

- degree of protection of electrical equipment - IP54 (standard);

- execution - general industrial.

Completion of the supplied crane equipment:

- electric rope hoists of MT type, end beams, geared motors for movement and lifting - manufactured by PodemCrane (Bulgaria);

- span bridge - welded box-shaped girder;

- lifting-lowering limit switch;

- limit switch for crane movement;

- limit switch for hoist movement;

- thermal protection of the hoist motor;

- light and sound signaling of the crane movement;

- load limiter;

- main contactor in the circuit;

- 2-speed radio control system;

- wired control panel;

- power supply to the crane - closed trolleys.

Both cranes have walk-through galleries and service platforms, the ability to accurately position, illuminate the working area and are equipped with safety devices. In addition, they are equipped with optical proximity sensors, which prevents the possibility of collisions during operation.

The delivered overhead cranes were assembled in a short time in the conditions of the existing production, then our installers performed commissioning, after which they carried out the necessary control tests with a load for static and dynamic loads. After the completion of all the work, the Customer's representatives were given a technical report on the installation of cranes, as well as passport and permits for their registration with the bodies of expert and technical supervision.

Currently, both new cranes are actively exploited, their use made it possible to speed up the technological process for the manufacture of various goods and the loading of finished products into vehicles, as well as to minimize the downtime of production equipment during service maintenance and repairs.

Related posts

- The 10-ton bridge crane for the boiler equipment plant was manufactured

- For the enterprise for the production of chemical products made 2 bridge cranes

- Overhead bridge crane for a feed mill

- An overhead crane with a span of 23 meters was made for a large manufacturer of agricultural equipment

- A modern overhead crane for an enterprise for the production of switchboard equipment and cable support systems was manufactured at the Kyiv Crane Machinery Plant