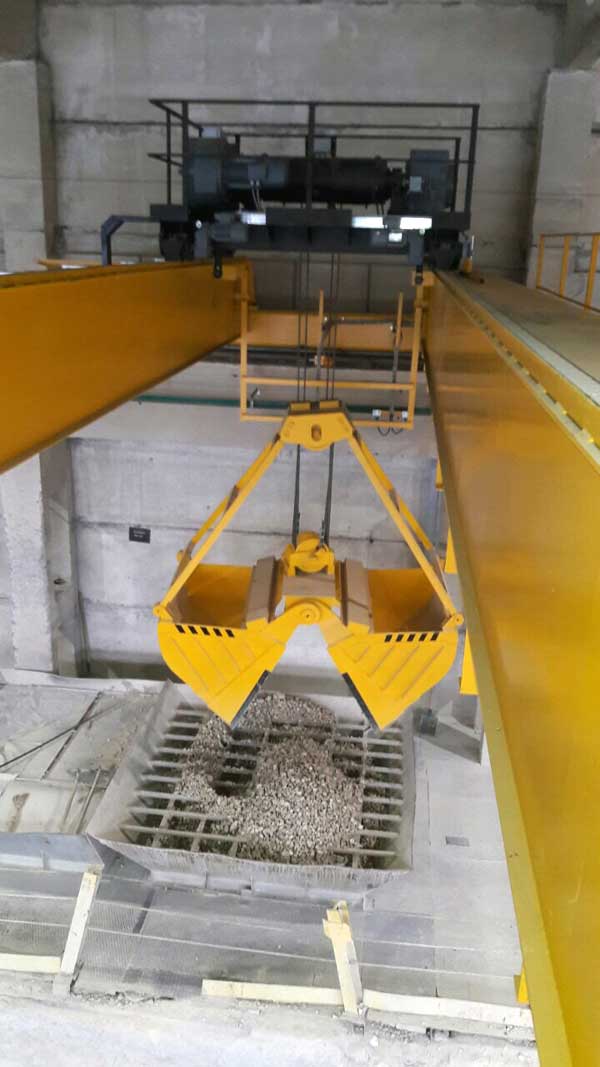

A new grab crane KMG-5.0-16.5-12.0-A7 has been manufactured at the «Kyiv Crane Machinery Plant LLC» for the largest producer of glass containers in Ukraine.

The Customer was assigned to our team the task of designing and producing, in the shortest possible time, a grab crane, which is necessary for solving urgent problems of increasing productivity and efficiency at the glass container production site. Crane equipment was extremely necessary for loading enriched sand, dolomite, soda from the bins into the crushing chambers, where the glass charge was being prepared.

Having carefully studied the peculiarities of the technological process and the plan of the site where the new crane equipment should be operated, the designers of Kyiv Crane Machinery Plant LLC offered the most optimal variant of its design and configuration, and also developed a phased plan for the implementation of works.

The main characteristics of the grab crane:

- lifting capacity - 5.0 tons;

- lifting height - 12.0 m;

- crane span - 16.5 m;

- cargo lifting / lowering speed - 0...12 m/min;

- trolley traveling speed - 0...30 m/min;

- crane moving speed - 0...40 m/min;

- group mode of operation according to ISO or GOST - A7 (very heavy).

Equipment supplied:

- span bridge (welded construction box beam) and crane trolley - manufactured by Kyiv Crane Machinery Plant LLC;

- hoist and end beams - Podem (Bulgaria);

- gearmotors for movement and lifting - Sew Eurodrive (Germany).

Electric cable and busbar supply systems to the crane - closed trolls. Smooth change of speed of lifting and movement is provided thanks to frequency regulation. For additional security, the crane is also equipped with limit switches for moving the hoist and the crane itself, light and sound alarms, and a load limiter. Control is carried out by an operator-crane operator from a closed cabin.

After manufacturing, the new crane was delivered to the place of operation and mounted by our employees within a few working days. Upon completion of installation and commissioning, all necessary test tests were carried out. At the moment, a new grab crane is being successfully operated.

Related posts

- Modern grab crane of the Kyiv Crane Machinery Plant for an incineration plant using Schneider Electric automation

- Manufactured 3 bridge cranes for a steel plant

- Kyiv Crane Machinery Plant LLC manufactured a magnetic bridge crane on the order of one of the largest mining and processing plants

- Three bridge cranes for a car repair plant

- Three bridge double-girder cranes were manufactured for loading and unloading metal products