Design of load-lifting cranes and crane equipment

Crane design is a complex process that requires careful consideration of customer requirements, analysis of loads, structural strength and stability, and compliance with all relevant standards and regulations.

Design stages

The design process of a crane can be divided into the following stages:

- Receiving technical specifications

To clearly understand the customer's requirements, representatives of the design and technology department inspect the customer's workshop and communicate with the personnel directly involved in the operation of the future crane. At this stage, it is important to clearly define the customer's needs, such as:

- Load capacity: Maximum weight the crane must lift.

- Lifting height: Maximum height to which the crane must lift the load.

- Working area: Hook approaches are required in the extreme positions of the cranes.

- Operating mode: Determining the intensity of equipment operation, work cycles.

- Speeds: Optimal speeds of crane mechanisms, such as trolley and crane movement, lifting/lowering.

- Control type: Manual, cabin, pendant control panel, radio control.

- Operating conditions: Street, indoor, explosive environment.

- Current supply: Optimal method of current supply to the crane.

- Budget: Customer's financial resources.

- Conceptual design

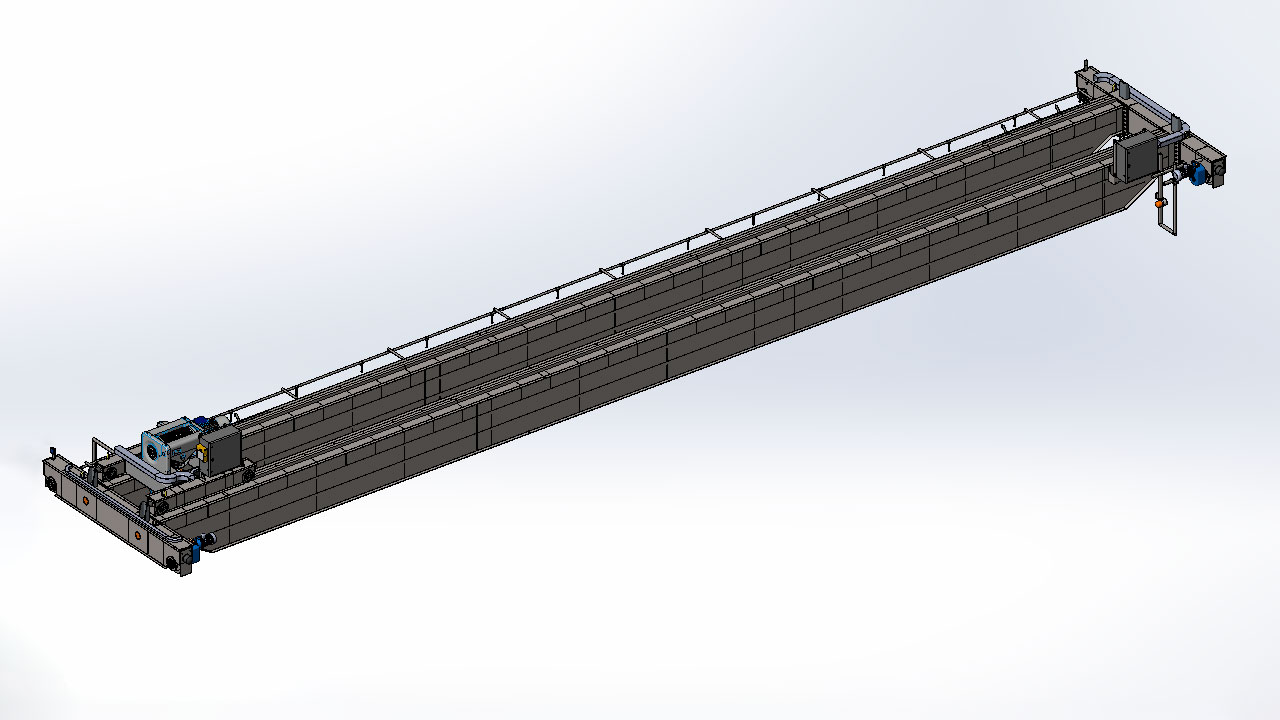

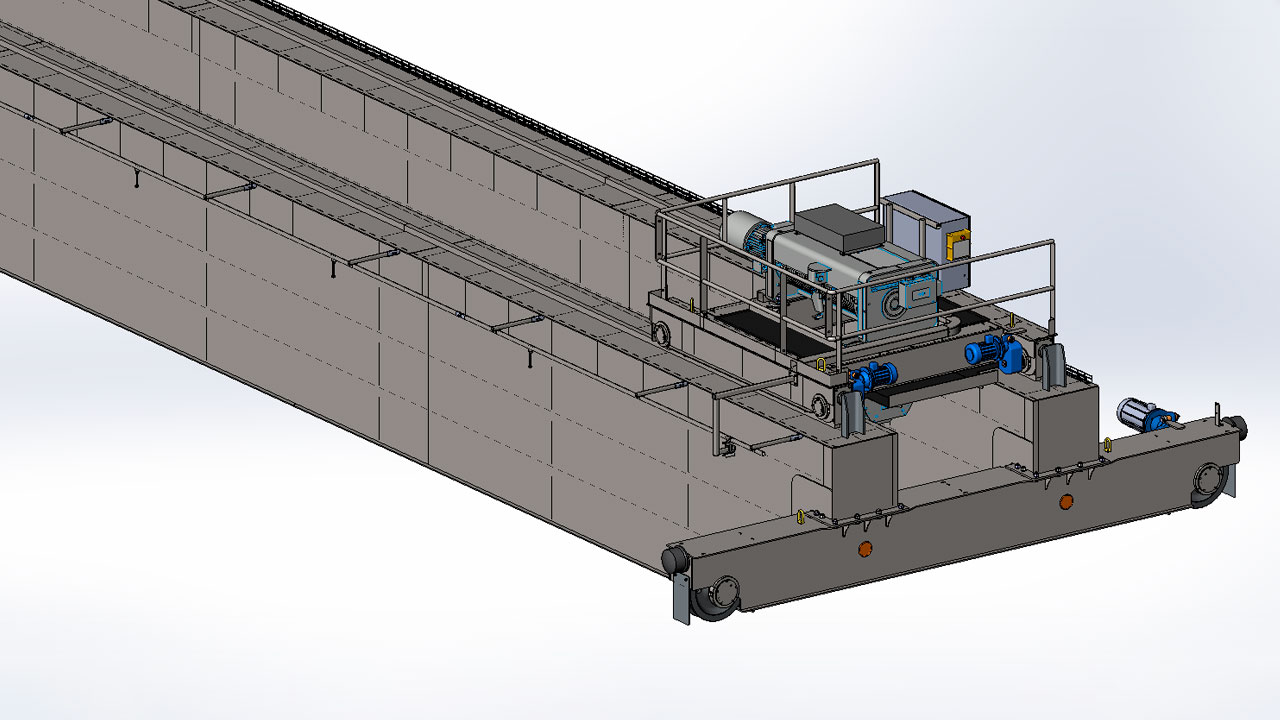

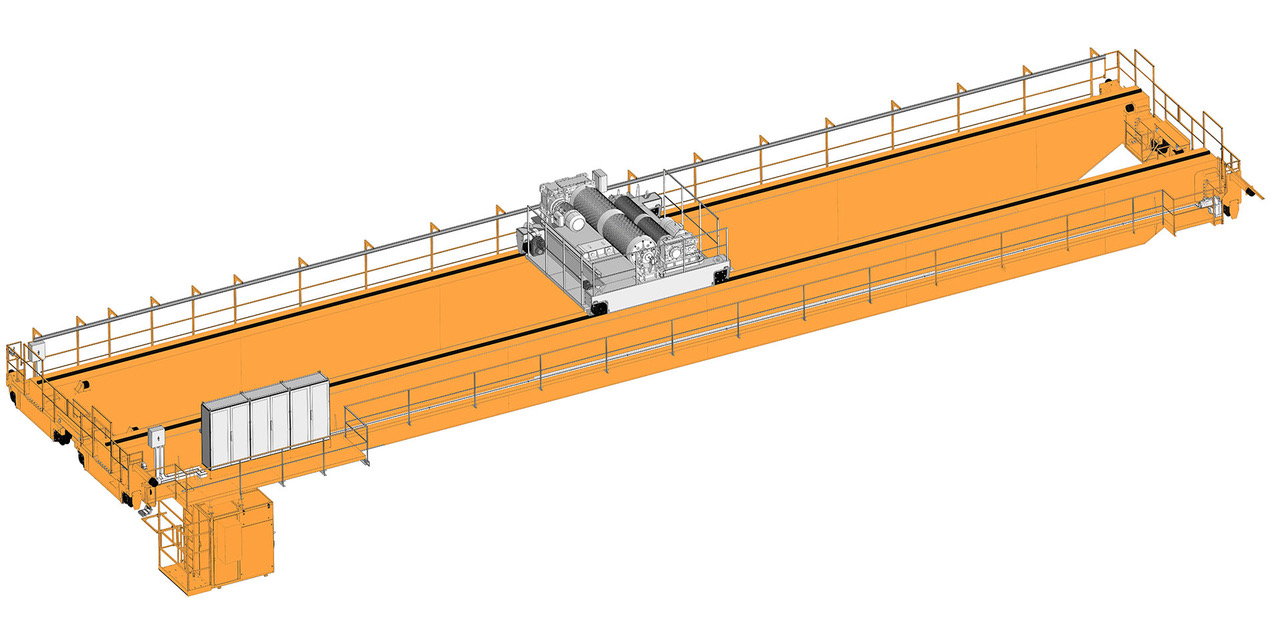

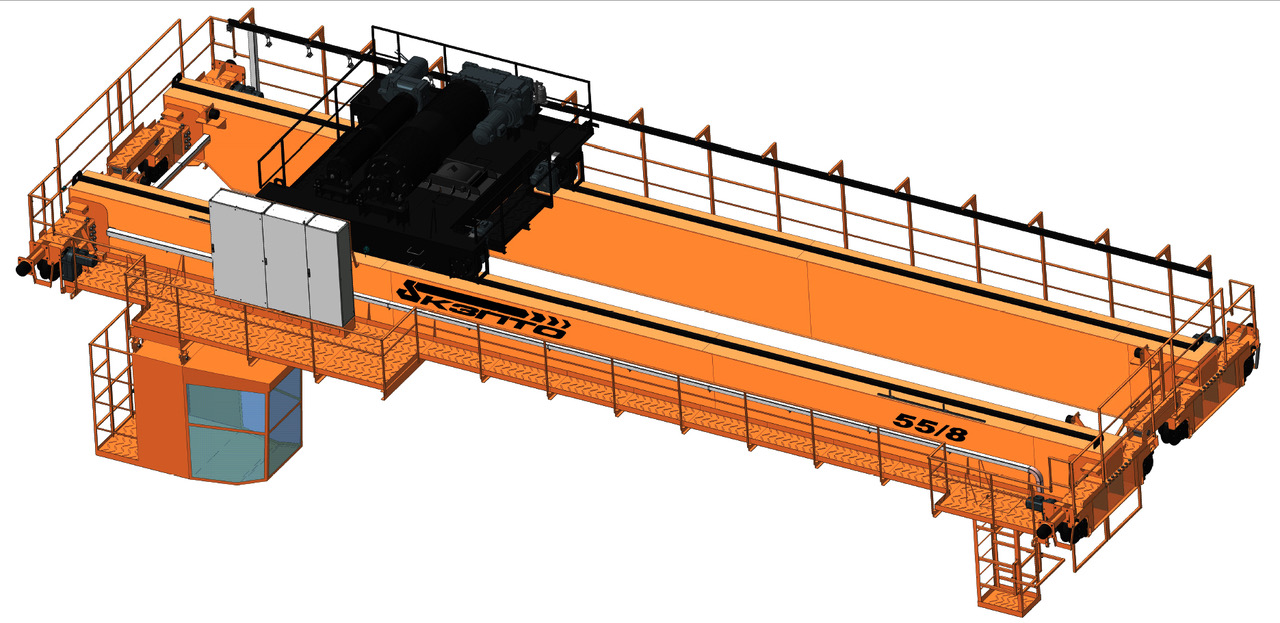

At this stage, the initial drawings and calculations of the crane are developed. At the customer's request, a technical project (drawing of the main units and mechanisms) can be performed. CAD systems are used.

- Detailed design

At this stage, detailed drawings and specifications of all crane components are developed. This includes:

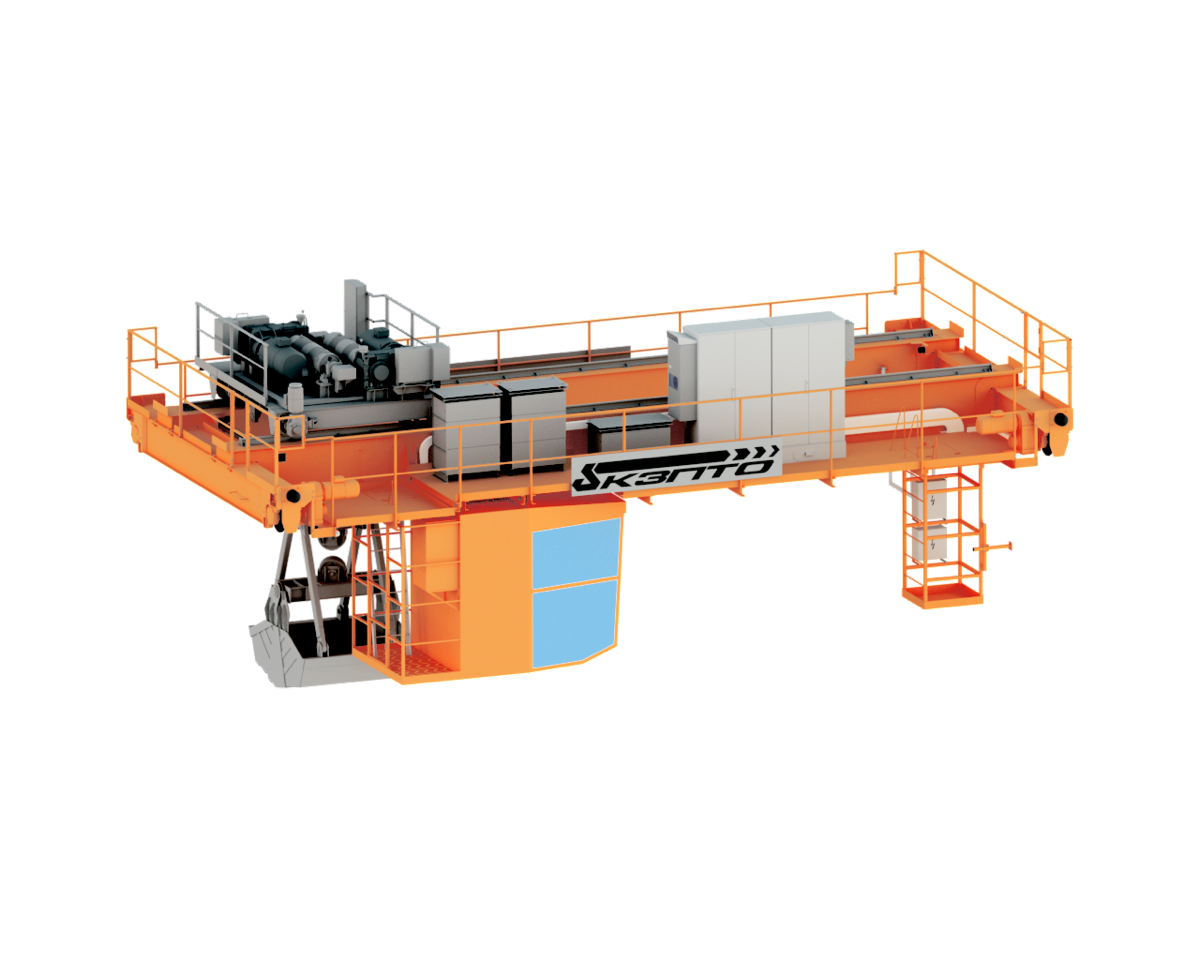

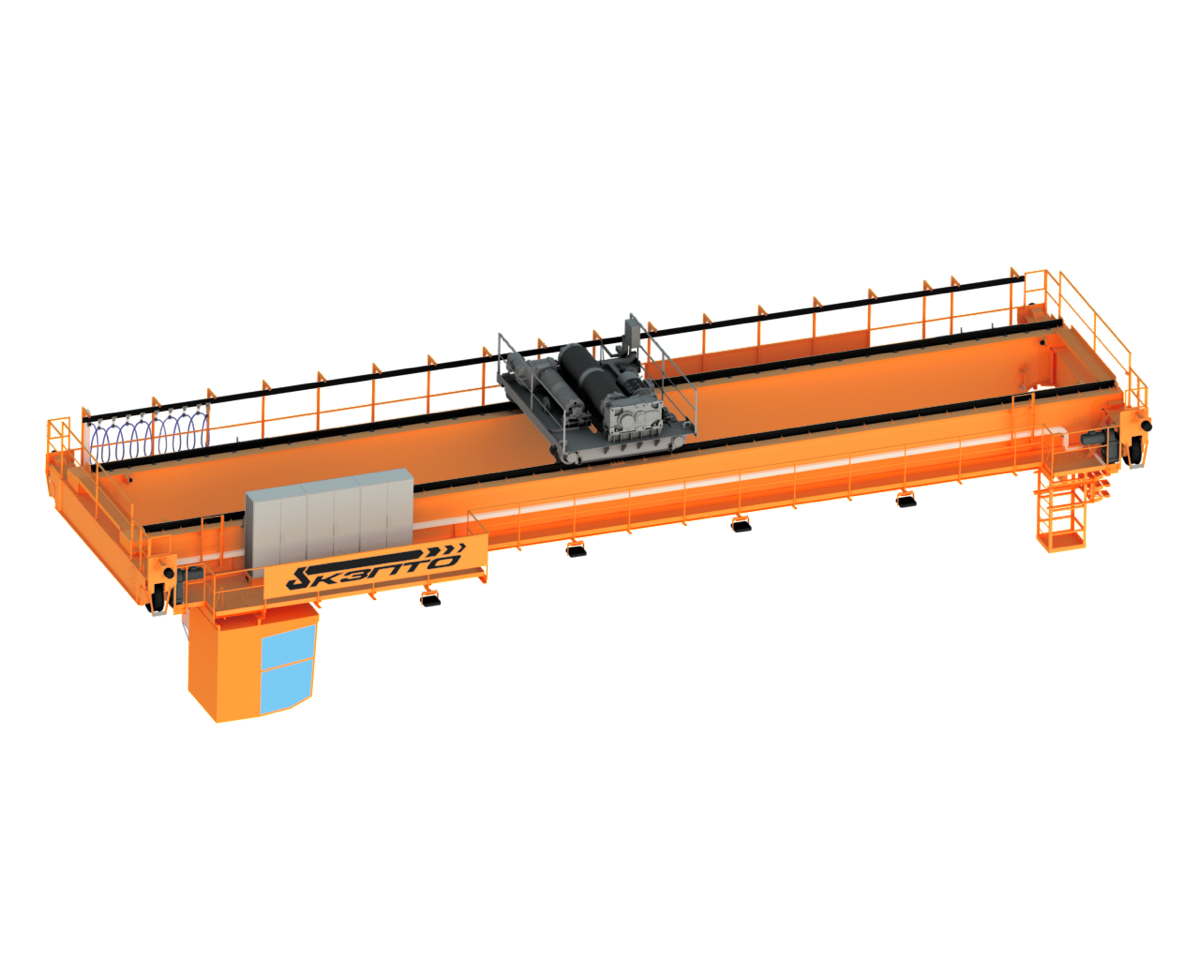

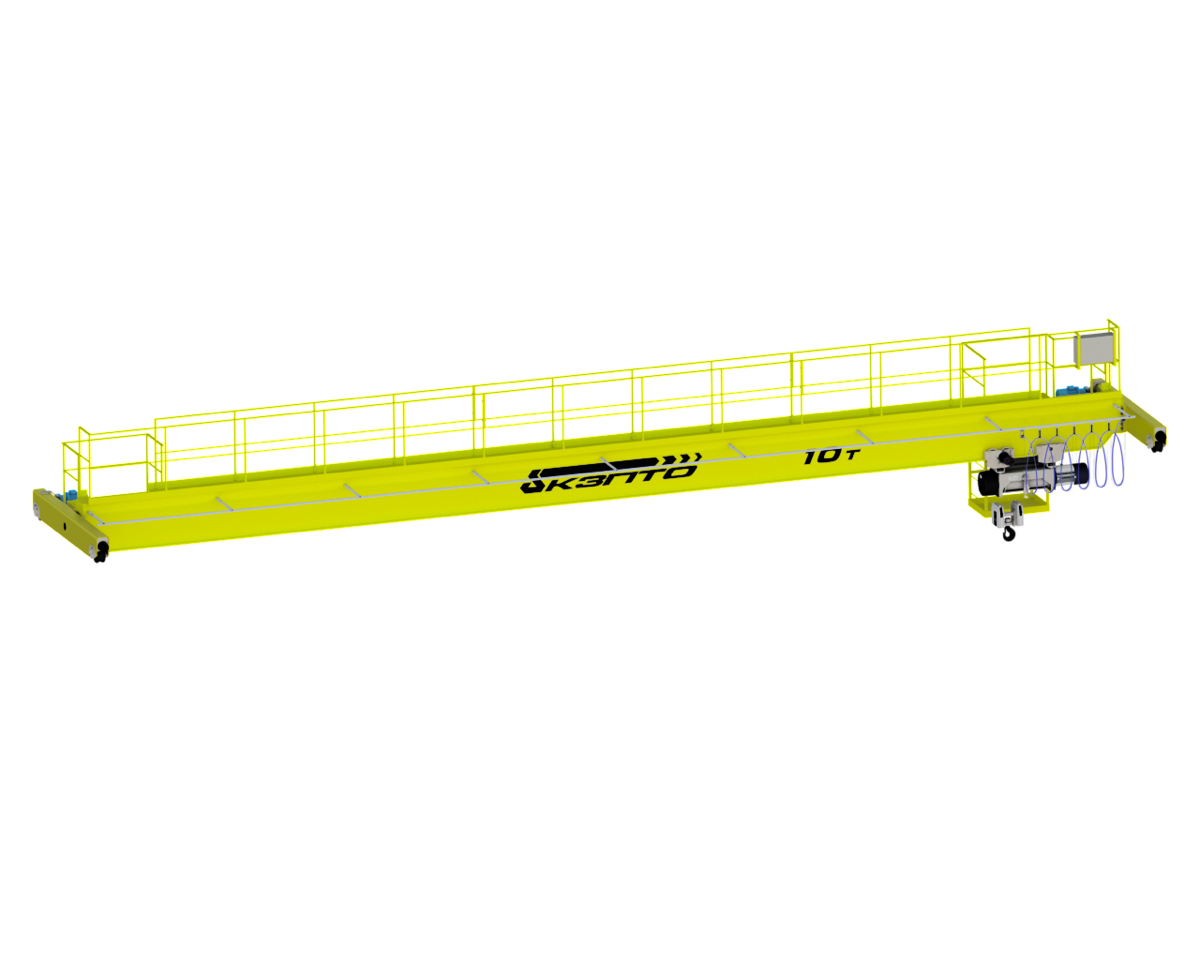

- Metal construction: Main beams, end beams, crane galleries, ladders, guards.

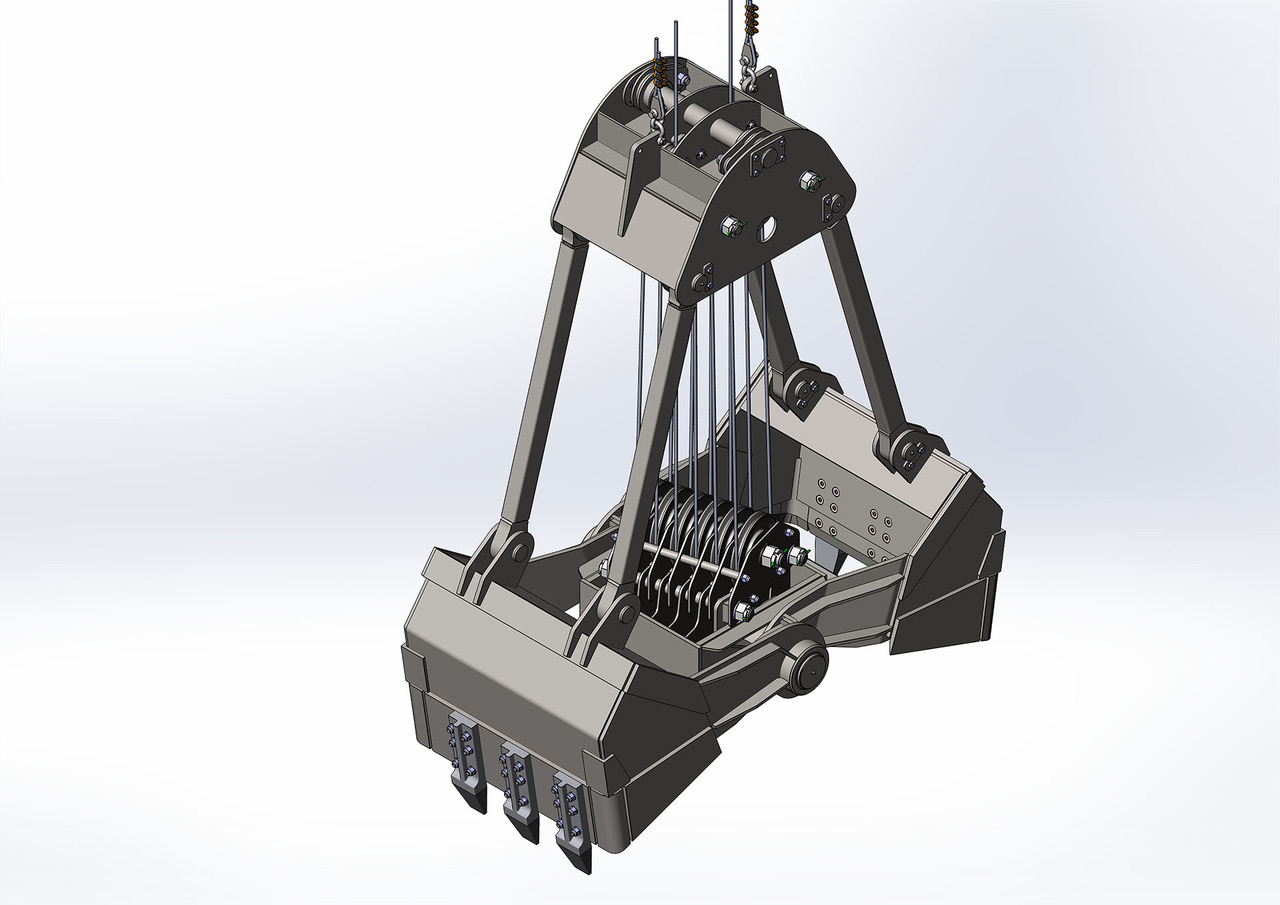

- Mechanisms: Lifting, traveling and turning mechanisms.

- Electrical equipment: Motors, brakes, cabins, controllers and other electrical equipment.

- Hydraulics: Hydraulic systems if used in the crane.

- Safety systems: Load limiters, limit switches, emergency brakes, buffers and other safety systems.

- Quality control and design analysis

At this stage, finite element modeling (FEM) programs such as SolidWorks are used to analyze the loads, stresses, and resistance of the crane. This ensures that the crane structure will withstand all expected loads while maintaining an optimal weight.

Important aspects of design

- Safety is the highest priority when designing and operating overhead cranes. All crane components must be made of quality materials and meet all safety requirements.

- Reliability: Cranes must be reliable and durable to ensure their trouble-free operation over a long period of time.

- Efficiency: Cranes must be designed to provide maximum productivity and energy efficiency.

- Ergonomics: Cranes must be comfortable and safe to operate.

Software

Various software packages are used for designing overhead cranes, including:

- CAD systems: For creating 2D and 3D crane drawings.

- Finite Element Analysis (FEM) programs: For analyzing crane loads, stresses, and resistance.

- Crane calculation programs For automating calculations related to crane design.

- Project management programs For planning, coordinating, and tracking the crane design process.

The design department of the Kyiv Crane Machinery Plant specializes in designing crane equipment in compliance with all necessary standards and regulations. Our qualified specialists use advanced methods and technologies to create crane equipment of high quality, reliability and safety.

Contact us today for advice on designing a crane that will meet all your needs.

Do you have questions?

Contact us now

or fill out the form below.

Related news

Integration of artificial intelligence into lifting cranes: challenges and prospects

In today’s world, where production efficiency has become a key factor …Two overhead cranes for Production and Design Association “MAANS” were manufactured at Kyiv Crane Machinery Plant

There is a war, but Kyiv Crane Machinery Plant, after relocation …About the work of the Kyiv Crane Machinery Plant in wartime

The life of Ukraine and the whole world is divided into …Manufactured two overhead cranes by order of the Prydniprovskyi Bio-TPP

By order of the Prydniprovskyi Bio-TPP, engaged in the production of …Kyiv Crane Machinery Plant – Industry Leader 2021

The Kyiv Crane Machinery Plant in 2021 produced and shipped more …

Other products

- Gantry cranes

- Overhead cranes

- Overhead cranes

- Suspended cranes

- Overhead bridge cranes

- Suspended bridge cranes

- Grab cranes

- Light portable gantry cranes

- Electric wire rope hoists

- Suspended undercrane rails

- Undercrane steel constructions

- Electric cable and busbar supply systems

- Jib cranes

- Explosion proof cranes

- Crane remote control

- Hand hoists

- Crane traverse

- Forklift

- Transfer trolley